ELEPOT Option List

Nitrogen Atmosphere Specification

The main unit is equipped with a pipe and a flow meter for injecting nitrogen gas. Oxidation or decarburization are likely to occur during the high-temperature heat treatment, and it leads to insufficient hardness. So, the chance of occurrence of oxidation or decarburization need to be reduced by lowering the oxygen concen-tration by filling the furnace with nitrogen gas. And, it can be expected to im-prove work efficiency in post-process.

1. Set the furnace flat, and make sure the flow meter is vertical.

2. Attach a hose band to the hose connection.

3. Hose connection point of the flow meter is attached to the main unit.

Inner Cover

By installing an inner cover in the furnace when injecting nitrogen gas, a highly sealed space can be created. As a result, the inside of the furnace is double-sealed, which can be expected to reduce oxidation and decarburization. Because of its design with the openable top lid, it is possible to take out only the work without taking out the entire inner cover after the processing.

※ Available only when using the "nitrogen atmosphere" option

Bottom Reinforcement

By reinforcing the bottom, the processing weight can be changed (remodeled) to "30kg or less" or "50kg or less", and heavy objects can be processed.

※ Applicable to LH model only

Processing by Hanging

Install a heat-resistant round bar on the frame of the furnace so that the work can be hung.

It is suitable for the situations such as "in an environment where the work cannot be put on the floor", "to reduce the warpage and distortion of the work", and “to process of thin plates and blades".

Double-Decker

If the inside of the furnace is not enough in the standard model, the height inside the furnace can be doubled by connecting the heater units and stacking them in two stages. This method is suitable for long objects. In addition, since three or more stages can be manufactured, please contact our sales department for de-tails.

Crucible and Cradle

Using a crucible in a furnace is suitable for operations such as melting.

・・We carry various crucibles.

・・We also make cradles based on the size of each crucible so that the crucible does not fall.

・Please contact our sales department for details. (about size etc.)

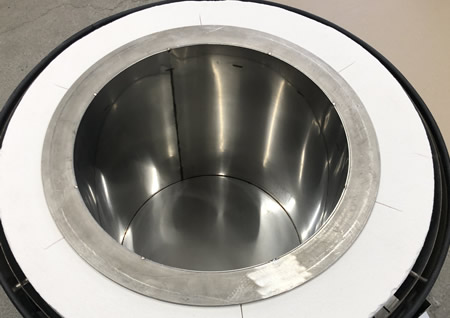

Furnace protection case

This product is a stainless steel cover and is a cylindrical case that covers the en-tire area from the edge of the furnace. Since the inside of the case is completely separated from the heater area, it protects heater and ceramic parts from "smoke and gas generated from work", “scale (Iron scrap and waste)“, and "met-al spilled during melting”.

Program Temperature Controller

Normal specifications do not allow multiple temperatures to be set. The “program temperature controller” allows you to set the temperature gradient up to “1 pat-tern / 9 steps”, expanding the range of use. You can raise the temperature through stages or slowly increase the temperature.

※ Natural cooling is the way to lower the temperature.

The Outlet on The Top Lid (mini lid is included)

It has an air outlet on the top lid to release gas during heating. When smoke or gas comes out of the work, it is discharged from the air outlet to reduce the load on the heater and ceramic part. It is more effective when used with the “furnace protection case”. Normal usage is also possible by closing the hole with the in-cluded mini lid.

Safety Timer

Under normal specifications, a buzzer sounds when the set temperature is reached and the holding time has elapsed, notifying that processing has been completed. At that time, the heater keeps ON and maintains the temperature. When using the “Safety Timer", the heater is automatically turned off after the holding time has elapsed instead of sounding the buzzer. It can also be used safe-ly as a measure against forgetting to turn off the power. It is also effective as a consideration for the neighbourhood by the buzzer sound at night work.

Voltage Change and Conversion

The voltage specifications can be changed to 220V / 380V / 400V for overseas use or when it needs to match the power supply in the factory. Please contact our sales department regarding overseas use and details.