ABOUT US

Comprehensive manufacturer of thermal equipment with 70 years of technology and experience

We started manufacturing various types of heat treatment equipment and drying equipment, in-cluding electric furnaces in 1950, as a comprehensive manufacturer of thermal equipment. We deal in a wide range of products to meet demands of our customers. From small-scale electric furnace “Elepot ®” to large-scale equipments for mass production, we offer the optimal equip-ment for each customer based on their needs - that is our strength as being a flexible SME. We do everything from design, manufacturing and control panel production all in-house with imple-mentation of both process control and quality control programs that ensures that our products and services meet customer’s expectations.

-

DESIGN

DESIGNDesigning optimal structure based on your needs

-

SHEET METAL

SHEET METALSheet metal assembly in-house - available for all sizes

-

FURNACE

FURNACEInherited traditional furnace technology

-

PAINTING

PAINTINGCorresponding to paint colour based on your request

-

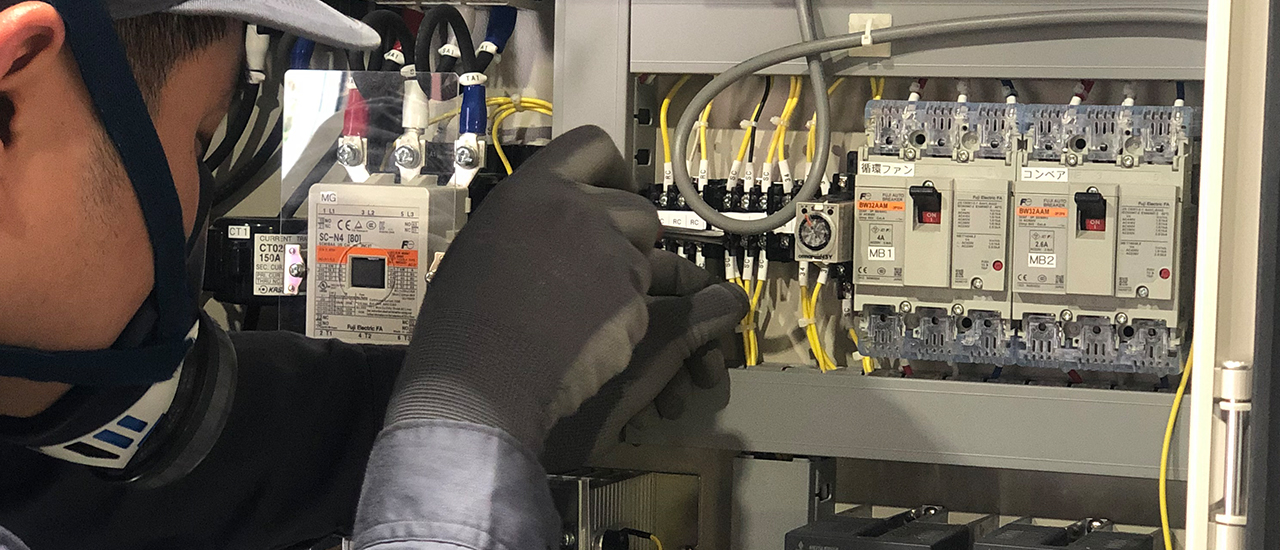

CONTROL PANEL

CONTROL PANELAll in-house production from design to wiring and assembling

PRODUCTS

ELEPOT

Weight saving by molding has enabled us to offer you the lowest price of the industry as well as compactness of the product. It’s designed for heating for steel quenching, tempering, annealing, melting, sintering, shrink fitting of metal, solid solution heat treatment and various other heat treatments.

* Compatible with a wide range of temperatures up to 1150℃ (It can be set in 1℃ units)

* Built-in safety feature to prevent overheating included

CUSTOM ELECTRIC FURNACE

Electric furnaces and heat treatment furnaces are designed and manufactured in-house based on your needs. We propose various options such as box type, conveyor belt type and trolley type, to make it an efficient and suitable structure for each customer.

SEAL PEEL MELTING TANK

A tank specified for dissolving seal peel solvent. An overheating prevention function is provided as standard and it gives you a safety and a sense of security during the operation.

ELEPAK

Non-decarburizing heat treatment of steel materials, vacuum heat treatment of steel materials (no vacuum furnace is required), bright heat treatment of copper alloys, aluminum alloys and other non-ferrous metals, also brazing work such as silver brazing, brass brazing and copper brazing etc. In addition, heat treatment is performed on items that need to prevent oxidation and combustion phenomena due to heating in air.